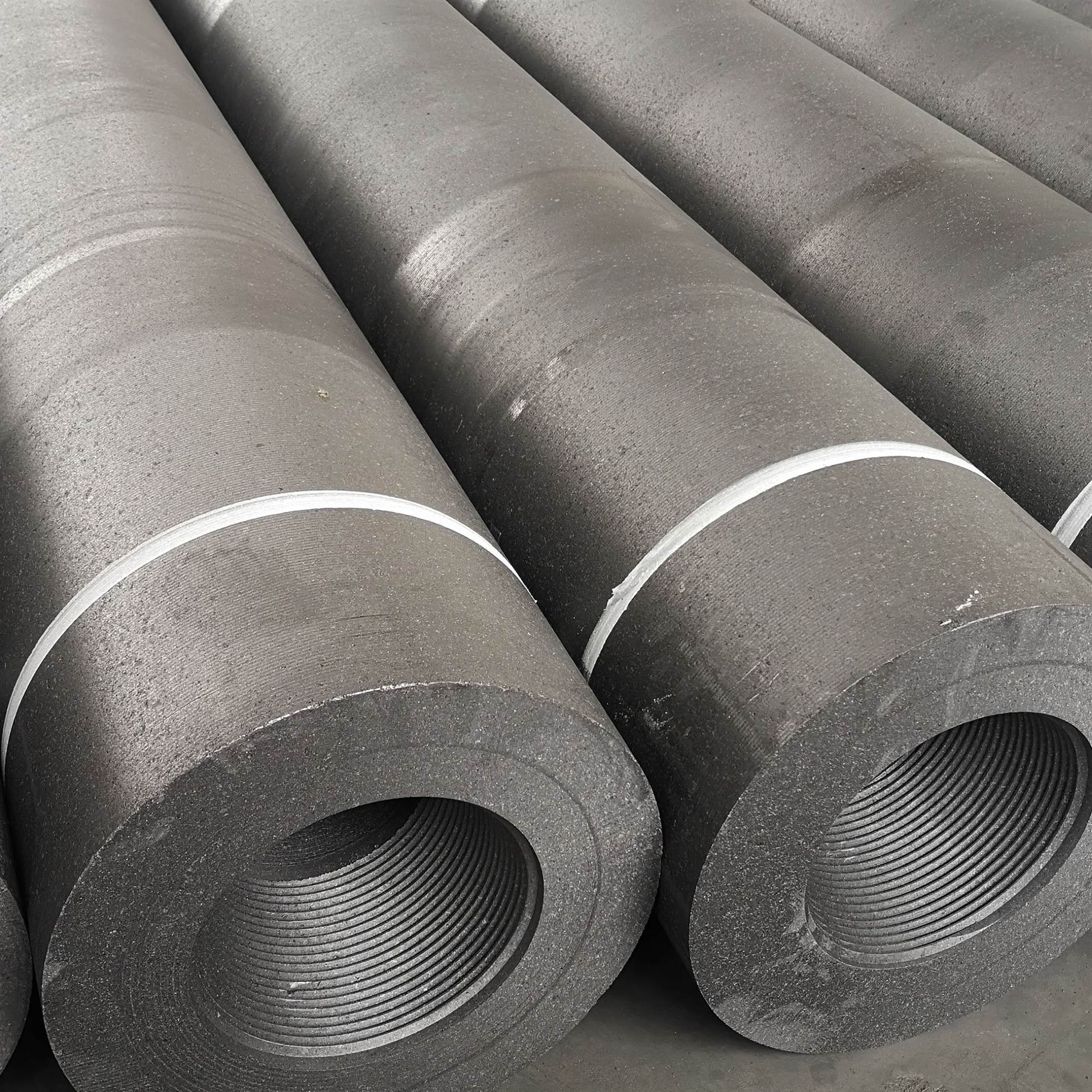

Processing of graphite electrode details

We need to know that the first wet graphite electrode should be dried before use, and check whether the thread inside the electrode hole is complete. When we use compressed air to clean the spare graphite electrode surface and hole internal thread, there shall be no oil or water; Avoid cleaning w...

Difference between calcined petroleum coke and graphitized carburizer

Many manufacturers will be a little vague about the type of carburizer when purchasing, so today we will look at the difference between calcined petroleum coke carburizer and graphitized carburizer. First, raw materials are raw petroleum coke. Second: smelting environment (1) graphitization carb...

How to optimize the production efficiency of graphite electrode

Even though each graphite electrode is an advanced piece of equipment and an excellent control system, it must still be operated according to production conditions and actual conditions. Therefore, people have been working on optimizing the production efficiency of graphite electrode. Graphite el...

The technology of batching affects the development of carbon products

In the 1980s, due to the short supply of carbon products and the high profit rate of carbon products, carbon enterprises generally had good economic benefits, and carbon enterprises rose rapidly throughout the country. However, due to the lack of advanced automatic carbon component, the whole car...

Select carburizing agent tips

The new process of carburizing agent smelting, whether cost or finished product performance, is better than the traditional large proportion of pig iron dosage, carburizing agent added to the metal smelting furnace, the use of high quality, excellent carburizing agent, can be the worst scrap stee...

Influence the price of carbon coke for steel

The use of carburizing agent in casting is the mainstream method. Because most of the carburizing agent is suitable for electric furnace, electric furnace feeding way is generally scrap steel and other raw materials together with carburizing agent. A small amount of carburizing agent can be added...

Quote Now

Quote Now